How Solar Energy Became Cheap

How Solar Became Cheap by Gregory Nemet was a rec from Ryan Orbuch. It details the history of Solar Power (aka Photovoltaics or PV), from initial development to ultimately large-scale deployment.

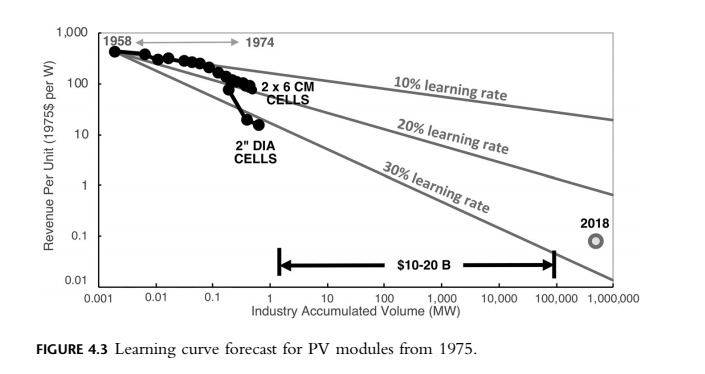

Why study solar in the first place? Well, solar has one of the most impressive 'learning curves' in the history of technology, when it comes to cost of deployment.

Photovoltaics started out as part of a satellite in 1957. Then, 1 MWh cost

Every single model we've had has been wrong, solar has gotten cheaper, faster than experts could believe!

Nemet's goal is to help prompt ideas for how other technologies might work this way, namely Direct Air Capture and Small Modular Reactors. Can we do the same sort of rapid devleopment with other forms of technology?

A few major themes to me stuck out as part of the development.

-

Early R&D at high costs. The US led the initial development of photovoltaics as part of the space race and satellite program. Launching up battery-powered satellites was unfeasible, so the government decided to fund and procure solar cells that had been developed in Bell Labs. These cells were exorbitantly expensive (1 mwh cost

20), but that didn't matter. They could be small and were part of a national effort to gain dominance in space. Sort of like the internet, the reason to find R&D was different than the eventual usage. -

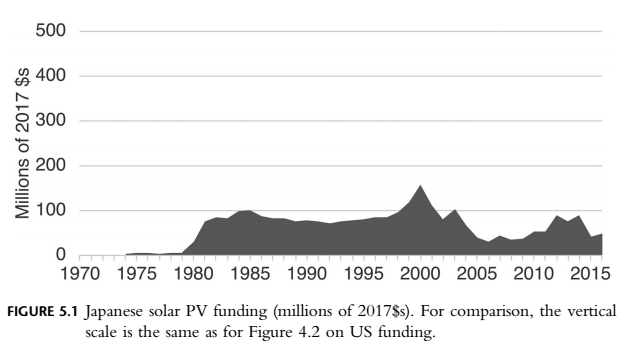

Shifting Global Leadership. Solar shifted first from the US to Japan to Germany and finally to China. Each country was able to take manufacturing information that worked for other countries earlier, and then incorporate those learnings into a new market. No single country led development for all of history.

-

Parochial Energy Biases. During the Arab Oil Embargo, the Nixon presidency vowed to reach a state of 'energy independence'. That's when the DOE was formed. Other countries wanted similar independence, but largely moved away from nuclear due to public perception (Germany, Japan). It wasn't necessarily a huge bet on solar that drove development, but a desire to move away from dependent energy sources.

-

Modular advantages. Because photovoltaics can be deployed both on a small and large scale, plants could effectively 'weather the storm' when demand for solar dried up. Consumer electronics (remember those Casio calculators?) used solar at a small scale, as did buoys and lighthouses. The manufacturing for these cells could be scaled up easily as demand grew.

-

Government incentives. Finally, none of this would have happened without government incentives. Solar succeeded because time and time again, governments offered feed-in-tarrifs and subsidies, leading the market.

The General Arc

- 1900: European and US scientists first understand the theory of PV in the 1900s (e.g. Einstein)

- 1954: Bell Labs creates the first photovoltaic and begins to start the first applications.

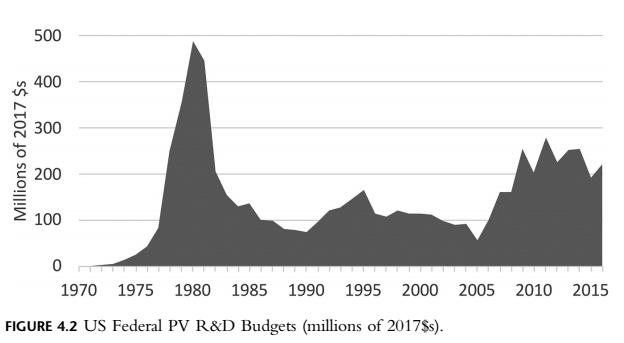

- 1973-1981: US R&D funding begins to achieve energy independence.

- 1990s: Japanese electronic conglomerates start serving niche markets in the 1980s and in 1994 launch the first rooftop subsidy program

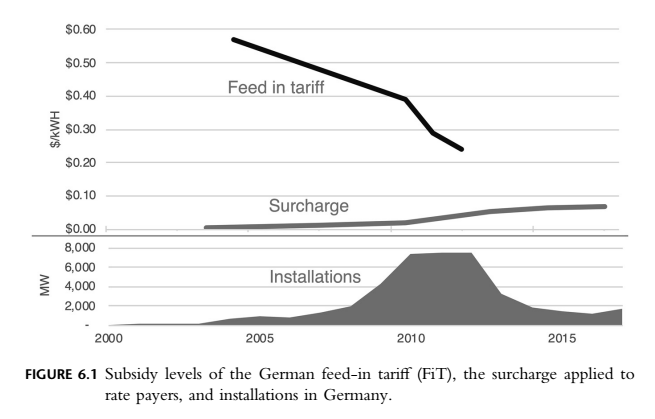

- 2000-2012: Germany's 200-billion feed-in tariff quadruples the market

- 2001-: Chinese entrepreneurs from Australia started building factories of gigawatt scale solar

An interesting piece of this arc, different countries ceded and updated controls over different times! There was no one leader championing solar forever.

Levers

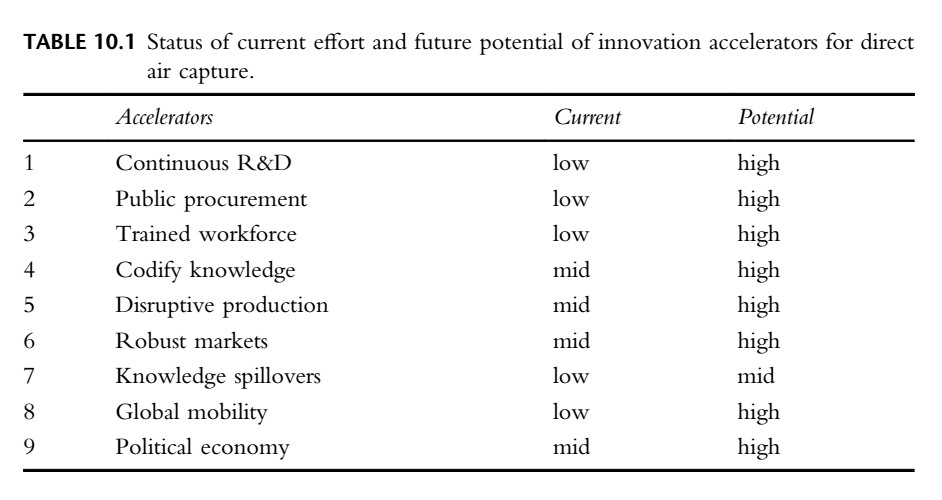

In the book, Nemet argues that there are 9 "innovation accelerators", or 9 ways to speed up the adoption of new tech.

- Continuous R&D

- Public procurement

- Trained workforce

- Codify knowledge

- Disruptive production

- Robust markets

- Knowledge spillovers

- Global mobility

- Political economy

Building the science

Scientific progress

- 1849: Becquerel discovers the photoelectric effect by exposing silver chloride to light and attaching it to platinum electrodes, which generate a current.

- 1905: Einstein explains the photoelectric effect, where light can travel as a wave or a particle. If the waves contain enough energy to be higher than the activation energy they will displace an electron.

- 1909: Milikan's Oil Drop Experiment confirms Einstein's theory by measuring the electric charge from a droplet of oil.. Less than proving the photoelectric effect, this just proves that charge/electrons are a quantifiable entity.

- 1941: An engineer at Bell Labs observes that a crystal he is using for radio will create voltage when exposed to light. The crystal had a crack in it at the "p-n junction" (or positive/negative junction). One side has Phosphorous with extra electrons, the other had Boron which was missing electrons.

- 1954: Bell Labs scientists patent the first "solar converting apparatus" which basically borrows from 8 other patents and fundamental research. Silicon emerged as the key material.

- 1958: Sputnik has launched and the US decides they need to launch more satellites. The US had launched previous satellites with batteries, but they were heavy. Solar provided an appealing alternative. From 1958-1969 the US spent about $50m on solar cells.

Creating the market

US Technology Push

- In the wake of the Arab Oil Embargo, the Nixon (and then Carter) administrations invested 1.7B into developing solar. DOE was also established during this point in time. Nixon pledged with "Project Independence" that the US wouldn't be dependent on any energy by 1980 and would invest 10B total.

- New contract structures were key. "Block Buy" procurement plus feed-in tariffs helped push for more builds. Block buying was a public procurement program in which ERDA purchased pre-specified amounts of PV from private firms.

Commercialization in Japan

- Started mostly in Japan. The government created a 'rooftop solar subsidy program', which caused 200,000 households to install PV systems from 1994-2005 with 0.8GW production. The government helped combine technology-push with demand-pull in a way that hadn't really been seen before.

- The oil crisis hit Japan even harder than it did the US because Japan had little-to-no domestic production. The government launched the Sunshine Project in 1974. It was similar to Project Independence that Nixon launched, but without nuclear as a power source. The Japanese were (somewhat understandably) skeptical of nuclear power given their history with it.

- Sharp led the way with solar-powered calculators, lighthouses, and buoys for navigation.

- Japan ceded this marketshare when the focus shifted from high-quality to low cost, and japan didn't bake in the German demand. They built their own supply chain for silicon.

Germany's Demand-Pull

- Germany's Green Party became the ruling partner in 1998, which passed legislation to favor PV. From 2004-2012, the Renewable Energy Law (EEG) led to the investment of 200b euros for 30GW of PV. Public support was similarly buoyed by anti-nuclear sentiment.

- Local installers thrived with the demand. Q-Cells (a producer) initially did well, but eventually lost out to low-cost Chinese manufacturing.

- Germany borrowed ideas from California (guaranteed purchase prices) and Japan (declining subsidy levels). The policy guaranteed that rooftop solar production to the grid would pay double the retail electricity rate ($0.50/kWh), and the tariff would decline by 5% per year.

- In 2005, the Green Party was voted out and replaced by parties sympathetic to the coal industry. Silicon prices in Germany continued to rise, making parties cite and 'end to the learning curve'.

- In 2011, the market grew by only 1% (it was growing at 50% previously) when the tariffs were cut. The result was that every german business went out of business!

- Q-Cells was the shining star that moved quickly, but eventually flamed out. Why? Two reasons. 1) They entered into expensive, long-term agreements for Silicon. When the Silicon market crashed in 2008, they were overpaying substantially. 2) Q-Cells spent millions on alternatives to crystallized solar, rather than focusing on improving the production process (as China did). Apparently there were some cultural issues too, Germany had to "get it right", China just "adopted if it works".

- "China had the right vision. When the world talked about 100MW, Chinese talked about 1GW. They had it right."

- Initially, the US & Germany built the "machines that build the solar" and shipped them to China. Chinese companies quickly reverse-engineered these machines and then started building their own.

Making it Cheap

Chinese Entrepreneurs

- By the numbers: China scaled up production 500x between 2000 and 2016. By 2007, they had produced more PV than any other country and by 2013 were installing more PV. By 2017, China had produced 70% of the world's PV!

- The biggest company was Suntech (mostly Australian citizens). Suntech raised capital from US markets, talent from Australia, and labor in China.

- Deng Xiaopeng create a program to send Chinese university students abroad. They would study elsewhere, and China would fund their tuition, travel, and rates with the goal of bringing back learnings and ideas!

- Suntech got initial funding from Chinese businesses who were pressured by a local government official. After 2 years they were producing modules at

3.48 per watt. - Realizing they needed more demand, Suntech focused marketing efforts on Germany, selling out the full 10MW line. For this new line, they needed a screen printer which they bought from a Japanese company producing their first one for 50%. They also needed a tool to passivate cells with titanium oxide (what is that?) that they bought secondhand from a friend for 400k.

- China passed a Renewable Energy Law in 2004, which took effect in 2006. It didn't so much as immediately speed production, as showing foreign investors that PV was a viable investment.

- Trouble started when recessions happened. Spain's Feed-in Tariff expired, reducing demand. Germany's market dried up as the green party fell out of power. Solar is capital intensive, and the financing means that you have to pay for production before any energy is produced. One of Suntech's subsidiaries had a $683m line of credit... and apparently that subsidiary had forged 500m euros in govt bonds. Yikes! Suntech defaulted on its debt and declared bankruptcy.

- Suntech competitors which had smaller balance sheets instead were selling to domestic Chinese markets. They were somewhat insulated from the global financial crisis, and able to take advantage of more and more government incentives.

Local learning

- In the US, about 2/3 of the cost of solar now come from 'soft costs' (contractor installation, marketing, etc).

- There's definitely a 'signaling' component here. If you have solar panels on your roof, they are extremely easy to see and show that you lead the charge. Residents influence other residents. Installers influence other installers.

- The fact that solar targeted residential meant that there wasn't a single big "push" to do solar everywhere. Instead, it was the result of thousands of micro-decisions happening across the country.

- There's an interesting idea of knowledge spillovers. The big concept here is that certain industries will share info around processes (e.g. here's how we do install panels more efficiently on steep roofs). This is a double-edge sword. On the one hand, it promotes competition and brings down costs. On the other, it removes some of the incentive for R&D. Why do something new if your competitors will immediately take it and use it?

Doing it again

The whole point of the book is: how can we apply what we've learned in solar to other pieces of tech?

Solar as a model to follow

- We need answers to three questions. 1) What were the drivers of solar's success? 2) What attributes of PV made it work with those drivers? 3) How can we apply this tech elsewhere?

- Solar is a 'high science' technology. Because it wasn't well-understood, the payoff to R&D was high, so people decided to do it!

- Solar converged on a 'dominant design' in 1985, which allowed manufacturers to specialize and drop the cost curve.

- Different markets rose at different points in time. No single market crash could destroy everything.

- Modular design (talked about before) is obviously key. If you can keep connecting individual pieces to scale up more and more, you can keep costs low and tracking to production. Because solar can be split into small panels, it can work for nearly any type of roof without significantly changing manufacturing.

- It's easy to ship and conspicuous.

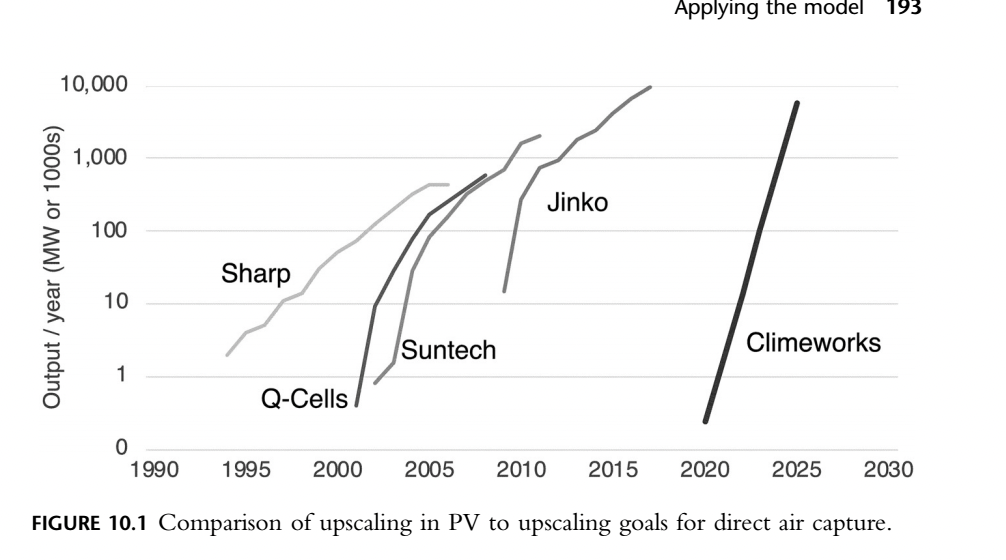

- Solar took about 60 years from initial scientific install to cheap cost, and about 80 years (projected) to widespread usage. It is the fastest example we have. If we model out DAC in the same way, it's closer to 2100 for widespread adoption.

- What works: fund R&D continuously, early stage procurement, trained workforce, preserve + codify knowledge, robust markets,

Applying the model

- Two areas to consider this elsewhere: DAC and Small Modular Reactors.

- A big 'a-ha' for me here is that DAC needs to become more modular and more widely deployed if we ever hope to make the learning curve for cheap sequestration work.

Direct Air Capture

- Climeworks needs a crazy learning curve in order to be competitive. There's an interesting history here: Climeworks initial plant is feeding CO2 to a greenhouse. Their cost for removal is $600/ton, and are starting to build modular units.

- Niche markets might pay $1,000 per ton of CO2. If that happens, DAC suddenly looks more attractive!

- Global Thermostat is another company doing this that hadn't been on my radar. They built their first plant in 2010. They are in the process of building a plant that will remove 50,000 tons per year at $150/ton.

- Carbon Engineering is looking to remove 1m tons of CO2 per year. It's focused on producing low-carbon liquid fuels, and they are building industrial scale plants (vs small modular ones).

- How are they doing on the axes? Not well. No public procurement. No trained workforce.

Small Modular Reactors

- Instead of operating at 500-1500MW, these operate closer to 50-250MW. Micro-reactors could be more like 1-10MW

- NuScale is designing an SMR with 60 MW capacity. They will test at Idaho National Lab in 2026

- Terrapower is building a 600MW demo plan by 2022.

- Transatomic

- U-Battery is creating a 4 MQ gas-cooled reactor.

- Oklo is building a 15MW heat-pipe cooled reactor.

- None of these have even been built yet, so there's a concern that we're close enough to get it up and running successfully.

Other models

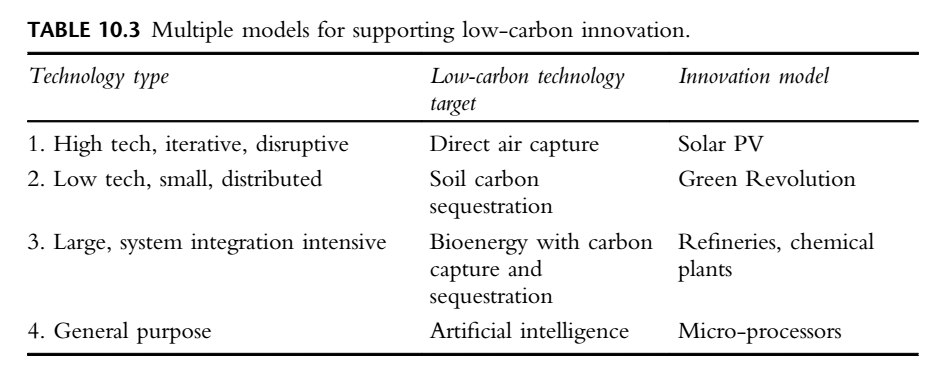

Lastly, there's some discussion of different "innovation models". I thought this was particularly interesting. Solar isn't the only example of what can work, but it is a good example when you have high-tech fundamental breakthroughs that need to happen.

- Type 1: high tech, iterative, disruptive: Solar PV, DAC

- Type 2: low tech, small, distributed: Soil carbon sequestration, green revolution

- Type 3: large, system integration: BECCS, refineries, chem plants

- Type 4: general purpose: AI, Microprocessors